Introduction

OPTICAL FIBRE TRENCH

An optical fibre trench (OFT) is a civil engineering work aiming at deploying optical fibre ducts or direct buried optical fibre cables. An OFT may be required for enabling a modification of the existing fibre infrastructure or to create a new or alternative path in respect to existing infrastructure (e.g. technical galleries, “caniveau”).

OFT are usually located

along roads and where future construction

activities will not overlap the

installation. Secondly, the trench should be

as direct as possible without causing

excessive damage to the roots of trees,

shrubs, or other vegetation along the route.

Depending on the method, trench width can

range from 60 cm to several meters and being

more than 100 cm deep [1].

During the

study phase, the project manager shall

specify the requirements concerning the

trench layout, the duct types, duct test

requirements, manhole specification as well

as the duct layout inside the trench and the

manhole. In addition, Project Manager shall ensure

that the installation is prepared and

executed correctly by establishing

acceptance milestones that will enable

periodical joint inspection for acceptance

of works per phase (e.g. trench digging,

ducts layout before refilling, filling up to

sand layer and green net, etc.).

|

|

Design criteria

WHEN IS AN OFT NEEDED?

The construction of OFTs are needed or

recommended when:

• No physical routes

(e.g. technical gallery) are existing

already between two different locations.

• The existing routes are overloaded,

preventing the correct installation of new

Optical Fibre Ducts (OFD) and cables.

•

The existing physical routes are not

suitable for blowing operation due to tight

changes of directions. The OFT built between

GT6 and GT796 is an example (see red line in

Figure 2).

Opposed to a cable tray, OFT

protects buried services with backfill

material delivering a high-level protection.

FIELD SURVEY AND WORK PREPARATION

The Project Manager shall identify all the existing underground services and formations prior to the design. At first, they need to establish the geographical position of all underground services, including deepness, by means of existing paper layout and GIS services. Further inspection on the fields are also to be done in order to validate the information coming from the existing documentation or to recuperate missing information. In particular, GPS surveys might be need to identify duct routes and manhole positions.

The services

identification request is addressed through

a “Declaration d’Intention de Commencement

de Travaux” (DICT) which shall be sent for

approval to Project Manager.

Any

trenching done near existing services should

be done very carefully to prevent accidental

damage to a service. Hand excavating might

be necessary to uncover known services prior

to commencing with mechanical excavation.

Areas where work is to be performed shall be cleared of all trees, shrubs, rubbish, and other objectionable material of any kind, which, if left in place, would interfere with the proper performance or completion of the contemplated work.

TECHNICAL SOLUTIONS

Two different solutions can be typically

adopted when placing ducts underground:

1. Place 160 mm or 200 mm pipes underground

in which will later be pulled inside 40 mm

or 50 mm OFD;

2.

Place 40 mm or 50 mm OFD directly

underground.

Solutions 1 is preferable

when a higher level of protection to the

underground services is to be delivered as

well as when the number and type of 40 mm

and 50 mm OFD is not defined yet.

Solution 2 is preferable for long OFT

(longer than 40 m) or if changes of

directions encountered prevent the bigger

pipes from being installed.

OFT ROUTE

The OFT shall be as straight as possible

in order to ease the pulling of buried ODF

or future cable installation. It is never

ideal to have directional changes, but if

unavoidable one shall keep the bending

radius as big as possible (at least 10 times

the duct/pipe diameter) and offset in the

same direction.

If a tight

change of directions (e.g. 90 degrees curve)

cannot be avoided, the installation of a

manhole (MH) shall be considered. Rigid

ducts shall then be cut at the MH

extremities and routed inside with flexible

duct.

The OFT route must be

documented on construction drawings for use

in the field. The construction drawings

should show all underground utilities and

obstacles.

Any deviation

between the planned OFT route and “as built”

OFT route should be noted on the

construction drawings and transferred to the

permanent route drawings and maps.

OFT PROFILE

It is immensely important for OFT to be

excavated to such a depth that the crown of

the OFD has at least 700 mm of backfill

cover. Where it is not possible to obtain

the specified minimum trench depth, Project

Manager

must be consulted. Concrete encasing is to

be avoided as it turns a previously flexible

duct into a long unreinforced concrete beam,

prone to fracture with ground movement.

A large concrete slab might be considered

over the crown as an additional and punctual

measure of protection if the requested depth

cannot be provided at a specific location.

The OFT bottom is at a depth of 1 m

and layered as following:

- • A 20 cm bed of sand;

- • The Optical Fibre ducts;

- • A covering of sand, 10 cm on top of the ducts;

- • The GREEN signaling net/mesh;

- • Then back filling and finally asphalt or topcoat.

Backfill material is to be

installed in layers not exceeding 30 cm,

with each layer compacted before the next is

added.

In addition, too narrow OFT will

not allow for proper duct installation

whereas too wide OFT will result

unnecessarily costly.

The minimum

distance for a new cable/duct to pass under

other network is 0.80 m. The minimum

distance for a new cable/duct to pass next

to other network is 0.80 m.

It is obligatory to respect the

minimum distances. Other distances will be

considered where the minimum distance cannot

be respected, dependent upon CERN approval.

The Project Manager must be notified of this prior to

commencing any works.

Project Manager shall

validate the final OFT construction plan

prior to the starting of the excavation

works.

Materials

BURIED OPTICAL FIBRE DUCTS (OFD)

OFD shall be suitable for buried

installation as well as for blowing of

microducts. The diameter can range from 25

mm to 50 mm.

OFD

must be installed without any kind of

intermediate joints between manholes (MHs).

If this cannot be possible, Project Manager shall be

informed during the study phase.

The

manufacturing length of the OFD shall take

into account the required total number of

OFD and each individual total installation

distance to prevent any intermediate joint.

Any damaged duct during the installation shall be removed and replaced by a new one. In case of minor damage or if the duct cannot be replaced, an intermediate transition chamber can be installed with the prior approval of Project Manager, to allow duct access in case of microduct blockage (i.e. this can be a L3T chamber 1 m by 1 m).

It is advisable to foresee a certain number of extra OFD. This will prevent from opening the OFT in case some non-conformities are detected during the tests. The following tables list the general characteristics for 40 mm and 50 mm buried OFD:

Table 1 - General characteristics

|

Applicable standard |

NFT 54-072 |

|

Material |

HDPE, PE80 or superior |

|

Max. coefficient of friction |

0.1 |

|

Max. internal pressure |

20 bar/4 hours at 20 ˚C |

|

Colour |

Black with four longitudinal

green lines |

|

Suitable for blowing

microducts and optical fibre cables |

|

Table 2 - Dimensions of 40 mm buried ducts

|

Internal diameter [mm] |

32 |

|

External diameter [mm] |

40 |

|

Tolerance ext. diameter [mm] |

-0.0 / + 0.6 |

|

Minimum wall thickness [mm] |

3.7 |

|

Fine longitudinal grooves |

52 |

Table 3 - Dimensions of 50 mm buried ducts

|

Internal diameter [mm] |

40 |

|

External diameter [mm] |

50 |

|

Tolerance ext. diameter [mm] |

-0.0 / + 0.7 |

|

Minimum wall thickness [mm] |

4.4 |

|

Fine longitudinal grooves |

52 |

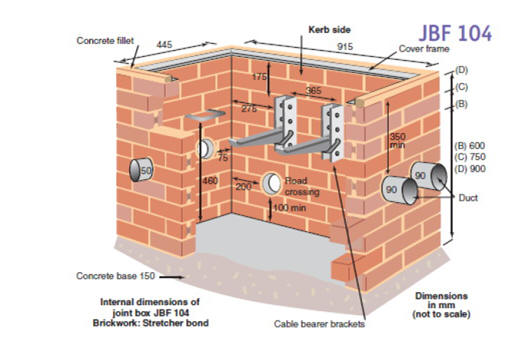

MANHOLE (MH)

MH are widely used during the creation of an OFT for two main reasons:

- ● To limit the overall distance of the OFT,

allowing intermediate (mid-point) blowing or

pulling. Indeed the MH allows splitting such

operations in several steps, decreasing the

friction of the component (i.e. pulling of

ducts or blowing of microducts).

Usually it is advisable to have access to the buried OFD at least every 0.5 km - ● To allow tight change of direction, bigger than the bending radius of the buried OFD.

Optical fibre manhole

MHs

shall be positioned as far away as possible

from road junctions in order to make easier

the excavation operations and the future

access.

Manhole are

to be sized sufficient to allow unobstructed

access for cable pulling and blowing as well

as to accommodate the bend radii of all

planned ducts.

Actual size will depend on

the number of duct entries the MH contains

and the purpose it is principally designed

for. The default manhole shall be a L5T.

In

case more than 12 OFDs are to be terminated,

a specific custom-made MH shall be designed.

MHs shall be large enough to accommodate

splice closures.

The installation of a MH deeper than 3

meters is not advisable as this will be

subject to “confined space” regulation.

OFD entry points into

MHs must be drilled, without cracking or

damaging the surrounding structure. Ideally,

any aperture shall be made in the building

fabric by core drilling or other vibration

free means.

OFD entries into MHs are to

be spaced at least 5 cm apart, both

vertically and horizontally, and at least 20

cm from the base and 25 cm from the adjacent

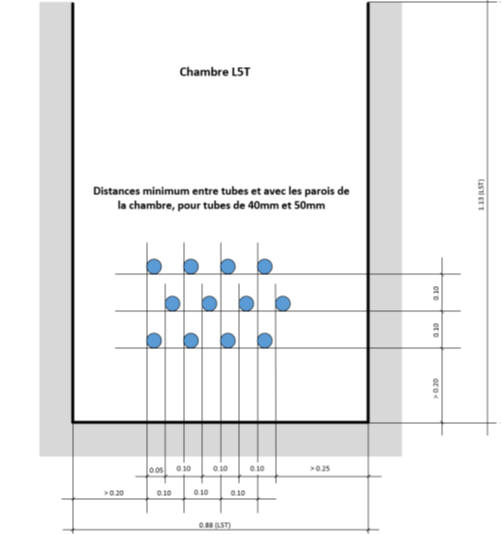

side walls (see below Figure).

A smaller distance can prevent coupling connectors from being correctly installed. Any aperture shall allow for a minimum of 1 cm of resin mortar to be applied around circumference of any OFD. OFD are to be cut so that a protrusion of at least 50 cm are left into the MHs. It is extremely important during the installation to ensure that distances between ducts are respected.

Figure 6 - OFD

entry points layout

MH shall be

equipped with a drainage system to allow

water drainage.

The MH lids shall be

complaint with safety rules and secured

against intrusion. All lids shall be equipped

with an automatic closing system with

anti-theft device.

Hinged

system are also to be installed in order to

prevent accidental damage to the underneath

services. It is advisable to install

triangle lids whenever possible in order to

reduce the overall weight of the cover.

Type and

frequency of road vehicles passing over the

lids are to be carefully considered when

choosing the robustness of the lids. Lids

installed on a road shall bear 400 kN

strength whereas others 250 kN.

Lids are

to bear a permanent identification label

defined by Project Manager.

Cablofils or

cable ladders are to be installed on the

long side of the MHs to allow optimal

positioning of ducts and cables

COUPLING CONNECTORS

Coupling connectors are to be

used inside MHs to join OFD. As for the OFD,

the connectors shall stand pressures higher

than 16 bar and be suitable for blowing

operation. It shall be compatible with all

possible materials (i.e. PE, PVC).

Datasheets of coupling connectors validated

and used at CERN are attached in [2].

Duct installation

All the works are to

be scheduled in compliance with the needs of

Project Manager.

External surface of OFD and

protected microducts shall be checked by

visual inspection prior and during the

installation. Crushed or damaged OFD shall

not be installed. OFDs crushed or damaged

during new installations shall be removed

and replaced.

It is the responsibility of

the contractor to ensure that every law

regarding traffic, safety, traffic signs and

barricading is complied with.

DUCT PULLING

When placing the OFD into an open OFT,

the bottom of the OFT must be reasonably

flat, free of horizontal and vertical bends,

and free of stones and debris. If

surrounding soil contains sharp stone or

other materials, the OFD should be insulated

with a protective layer of fine sand

(approximately 20 cm under and above the

duct). OFD extremities from drum must be

carefully inspected before pulling. No

visual damage in outer sheath shall be

accepted.

OFD shall be as straight as

possible, laid in a straight line between

MHs. In case of any directional changes, the

bending radius shall stay as big as

possible. A minimum bending radius of 10

times the outer OFD diameter is to be

maintained.

When possible, all OFD shall

be sloped properly so the will drain into

the MH and away from the building entries.

OFD can be placed into an open OFT either

directly from a drum or from temporarily

laid alongside the OFT and placed later on.

It is not recommended to hang OFD on fences,

barriers, etc.

When placing multiple OFD

in a single OFT simultaneously, it is

important not to cross or twist the OFD

inside the OFT. When installing large

quantities of OFD it is possible to stack

them one on top of the other in addition to

side-by-side.

However, the OFD are to be

spaced at least 2 cm apart, both vertically

and horizontally, and attached together by

means of an OFD spacer. If ducts are to be

deployed in more than one group another,

these shall be separated apart by a 10 cm

sand layer.

The distance between is to be

checked every 10 meters in the straight

trenches and every one meter in the curved

trenches. Checks is to be made before the

trench covered by the sand or concrete

layer. The measured distances will be

reported in a data sheet.

OFD spacers

should be installed every three meters. They

prevent OFD from twisting over and around

each other. By keeping the OFD in straight

alignment, cable blowing and/or pulling

tensions will be reduced. A detectable

GREEN signaling net shall be installed in

all OFT. The tape shall be laid according to

the layout in Figure 5. Pulling ropes

shall be installed and left in every new

OFD, following OFD laying operations and

satisfactory tests.

DUCT TERMINATION

At approximately 5 meters from the MH, the

OFD formation shall open out to provide the

sufficient gap between each OFD.

OFD

shall enter and exit MHs in line with the

direction of the route, for them to be

coupled without any obvious effort, as a

continuous OFD.

Unless otherwise required

by Project Manager, the OFDs shall enter a MH at such

depths that will ensure a minimum clearance

of 60 cm below the ground surface.

All

OFD entries and exits MHs must have a

watertight seal, to prevent water, dust or

any other foreign articles from entering

into the OFD, and a proper waterproof label.

Duct integrity tests

OFD

are to be tested and proved with a

calibration and pressure test.

The tests

shall be performed after the installation of

all OFD with the OFD covered by the sand or

concrete layer.

In case of concrete

layer, it is advisable to do the calibration

tests before and after the concrete layer is

deployed. It is also advisable to verify

that all ducts have a good caudal of air at

the exit prior the starting of the tests.

The contractor shall organize, supply

the necessary test tools and execute the

checks and tests.

The contractor shall

communicate to Project Manager the dates of

the tests with at least two working days’

notice.

DUCTS CLEANING AND CALIBRATION TEST

- Each OFD installed

shall undergo a cleaning and calibration

test at the end of installation. The

OFDs shall be cleaned over their whole

length by sending a sponge of appropriate

diameter.

The uniformity of the internal surface shall be assured by conducting a calibration test of the duct. This shall be done by sending an appropriate caliber (~>=85% inner duct diameter) in the OFD under pressure. The caliber shall go across the installed ducts without interference. Any non-conformity shall be immediately reported to Project Manager. After the test, the OFD extremities shall be sealed to avoid the entrance of dust and external bodies that could jeopardize the pulling of the cables.

Here the sequence of tasks for cleaning and calibrating the OFDs.

• Foam Sponge Test - cleaning the duct:

§ A sponge is typically 100 mm in length and 2 times the OFD diameter.

§ Wet the sponge slightly with blowing lubricant.

§ Place the tight-fitting foam sponge inside the OFD.

§ At a maximum pressure of 4 bars, blow the sponge through the OFD.

§ If excess water or dirt exits the OFD, repeat the process.

§ Have a sponge catcher in place at the far end to catch the sponge when it emerges.

• Calibration Test - check for bends, kinks or blockages:

§ The sponge test MUST precede this test - a calibre can damage a dirty duct.

§ The calibre must be 80% of the duct diameter

§ At a maximum pressure of 4 bars, blow the sponge through the OFD.

§ At the receiving end, a catcher must be used. Note that a flying calibre can cause injury and/or damage!

§ Always inspect the condition of the emerged calibre, visible grooves is an indication of duct indents.

DUCTS PRESSURE TEST

Each OFD installed shall undergo a pressure

test to certify the tightness. Each OFD with

a diameter less than 50 mm shall be

pressurized with air or nitrogen at 10 bars

for a duration of one hour. Conditions can

be 2 bars for a duration of three hour in

case the OFD diameter is larger than 100 mm.

The admissible pressure drop at the end of

the test is 10% of the initial pressure. The

pressure shall be recorded every five

minutes during the entire test period.

Here the sequence of tasks for testing the

OFDs:

Pressure Test - check for coupler

leaks or OFD punctures:

§ Fit a

high-pressure end-cap to the OFD under test

on the far-side.

§ Gradually build the

pressure up to 10 bars.

§ Test all

coupling used for this test for leaks, using

soap, water and a sponge.

§ Connect the

air feed and leave this open until the

pressure in OFD stabilizes at 10 bars.

§

Close the air valve on the test assembly and

monitor the pressure gauge.

If an OFD

fails the integrity test, the duct shall be

rejected and Project Manager informed.

Documentation

The following documents

shall be provided to Project Manager at the end of the

works:

• The “as-built” construction

drawing of the OFT;

• The drawing showing

how OFDs are being terminated in the MH

(i.e. entry positions, labels);

• The

drawing showing where duct joints where

installed, if any;

• Details of any

non-conformity or suspicious signal

encountered during the installation and

test;

• The test report.

More info can be found

here