What is the meaning of discovery monocrystalline silicon made by Czochralski?

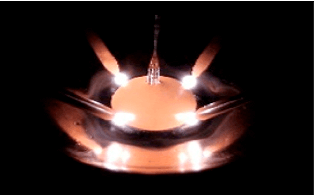

Jon Czochralski

discovered in 1916 what now is called

Czochralski Process, a process to growth large single

semiconductor crystals of exceptional quality

and for the production of silicon wafers.

Those can measure up to 2m by 0.5m and can be made

within 30 to 48 hours. Then they can be chipped off

in very thin sheets and used for the production of microprocessors

Czochralski made his discovery by accident in 1916 while

investigating the crystallization rates of

metals.

What has caused interest in his discovery after so many years ?

Czochralski method

was completely forgotten for years. In fact,

in the

first part of the last century it was used

mainly for studying the grow rate of some

metals.

However, after the war and the

discovery of the transistor,

scientists suddently became interested in the growth

of silicon.

In fact, the increasing demand

of semiconductor electronic materials in

1950 led the Americans G.K. Teal and J.B.

Little from Bell Telephone Laboratories to

rediscover and widely apply this growth

method, giving it a world-wide fame to the

Czochralski method as the best process to grow large single

crystals on an industrial scale.

The

natural growth process would take much long and would be limited to very small

sizes of crystals, making it unviable for

industrial production of electronic devices.

The level of miniaturization achieved today would be

otherwise impossible to

attain. Basically, computers would still be

the size of an entire room, instead of the

palm of your hand.

How the monocrystalline silicon is used today?

The Czochralski process

is the base of semiconductor chips.

In

fact the monocrystalline silicon form is

used extensively in solid-state devices, in

computers, and microelectronics industry due

to its incredible quality and the

total absence imperfections in the

silicon microstructure.

Without the

crystalline perfection, it would be

impossible to build high integrated devices

with millions of transistor-based circuits.

Monocrystalline silicon plays also an

important role in the photovoltaic

industries where high efficiency solar cells

use the sun’s light to produce water heating

as well as domestic and industrial electricity.

Even

at CERN, in all the experiments operating in

the LHC accelerator, silicon wafers grown

with Czochralski process are widely used.

Radiation silicon detectors grown with the Czochralski

process are considered to be one of the best

candidates for future high-energy

physic experiments due to their exceptional

quality and radiation hardness proprieties.

How Czochralski's discovery influenced the development of our civilization?

Large size silicon

monocrystals, grown with Czochralski

process, have been used for over 40 years

now as a standard material in semiconductor

industry all over the world. Some scientific

areas, such as the microelectronics, the

solid state physics as well as the material

science, which created the foundation of

modern technology, owe, at least in part,

their progress and present position to the

Czochralski's discovery.

His discovery

has proven vital for electronic revolution

as we know it today and it has been the key

for the computer diffusion that has brought

all the house Personal Computers

smartphones. From the perspective of almost

the past century the common opinion of the

scientific community recognized him as a

great scientist who has laid the foundation

for the development of the global

electronics.

Are you aware of any other discoveries and inventions made by Jan Czochralski?

It's not only on

crystals that Czochralski worked on. During

his entire professional life he was a very

active and competent scientist, able to

identify most important aspects of physical

problems, to understand them, and finally to

find successful application of the conceived

ideas.

As matter of fact he made

discoveries in metallurgy used for the

development of wheels that allowed trains to

go much faster than before.

Czochralski

was also a pioneer in what is now described

as technology transfer. He register a high

number of patents in Germany and Poland. In

addition during the war, when he worked at

the Technical University of Warsaw, he

developed an easily manufacturable grenade

for the Polish resistance.

To conclude,

history confirms that he was distinguished

scientist and inventor. It should be also

underlined that he had very modern views on

the role of engineering sciences. Much of

his research was driven by the needs of

industry and the search for new technologies

Do you think that the graphene production on an industrial scale is/would be a breakthrough similar to the silicon?

Both science and the

industry place high hopes in graphene.

It's considered as the wonder material of

our century with the power to revolutionise

micro-electronics. Just one atom thick, the

novel form of carbon is the world's thinnest

and strongest nano-material, almost

transparent and able to conduct electricity

and heat.

Graphene transistors would in

theory be able to run at faster speeds and

cope with higher temperatures than today's

classic silicon computer chips. That would

solve a fast-growing problem chip engineers

are facing: boost power and

shrink semiconductor size without

raising temperatures. Graphene's

transparency also means it could potentially

be used in touch screens and even solar

cells, and when mixed with plastics would

provide light but super-strong composite

materials for next-generation planes and

cars.

The problem so far came from a

lack of methods to grow it.

Single sheets of graphene are hard to

produce and even harder to make on an

appropriate substrate. While it is currently

possible to produce graphene layers,

relatively large ones can only be made on a

metal base. That hampers graphene's

electronics potential. Without such a base,

current techniques only allow for a maximum

layer surface of four square inches (25

square centimetres).

Now Polish

scientists, from the Institute of Electronic

Materials Technology claimed to discover a new method to produce entire

layers of graphene, a move that should help

to propel it out of the lab and push it into

everyday's life. This is an important step

forward on the path to the production of

transistors and then integrated circuits

made of graphene.

The great hope is that,

as happened to Czocharlski in the past, the

polish scientists can develop a new and

reliable production process that will

revoluzionize the world.

If there is a possibility to combine silicon and graphene? How?

Graphene poses a

significant challenge, though: in contact

with other materials it changes

significantly and loses its potential.

Some scientists were able to combine silicon

and graphene, in particular in the domain of

radiation detector. They were able to

combine graphene light detectors with

standard silicon chip.

The

super-conductivity and transparency of

graphene, could make it the ideal candidate

to produce super-efficient solar cells: it

does not stop incoming light rays and allows

electricity to move fast through its carbon

atom lattice.

This was achieved by

growing graphene on a copper foil, then

moving it to a glass substrate and coating

it with a silicon film. Measurements showed

that silicon-coated graphene has a power

conducting capacity 30 times higher than

traditional materials. This is an important

achievement that, however, still requires

lots of efforts.

But the big hope of

micro-electronic engineers is to use

graphene, combined with silicon, for future

CPUs working at 1THz — that means 1000GHz.

Also in this case, a big effort should be

put in place for the development of a

reliable industrial process capable to

combine graphite and other semiconductors.

References

- S. Meroli, Two growth techniques for mono-crystalline silicon: Czochralski vs Float Zone, (2012).

Anything missing? Write it here