Radiation detectors

made of silicon are cost effective and have

excellent position resolution.

Therefore, they are widely used for track

finding and particle analysis in large

high-energy physics experiments.

Exposure of the silicon material to

particle radiation causes irreversible

defects that deteriorate the performance

of the silicon detectors. Normally an

approach to improve the radiation hardness

of the silicon material is to increased

oxygen concentration in silicon material.

Exposure of the silicon material to particle radiation

Exposure of the silicon material to

particle radiation causes irreversible

defects that diminish the performance of the

silicon detectors. Thus, improving the

radiation hardness of the detectors is a

very important research subject in

experimental particle physics. Silicon

detectors are pn-junction devices operating

at full depletion. Radiation induced defects

diminish the performance of the silicon

devices in two principal ways.

First, in

the silicon material, the defects create generation-recombination

centres that decrease the minority

carrier diffusion length and increase the

leakage current with relation to the

irradiation dose. Thus, the electrical

signal created by the particle traversing

the detector becomes difficult to

distinguish from the background noise.

Second, lattice defects change the effective

resistivity of the silicon.

Consequently,

the operating voltage needed for the full

depletion of the detector changes and

gradually may exceed the breakdown voltage

of the device. Additionally, as the

irradiation dose increases, the defects

eventually change the type of conductivity

of the silicon from n-type to p-type.

The deterioration of the silicon detectors

in particle radiation is the most serious

limitation of the long-term performance of

large modern particle physics experiments.

Thus, all the results obtained in the

improvement of radiation hardness of

silicon detectors are directly applicable to

the international community of high-energy

physics, including future CERN experiments.

In addition, the results can be exploited in

space research since similar detectors are

used to measure high particle radiation

fields in space.

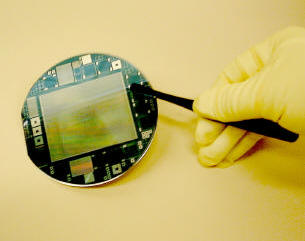

Fig 1.

Radiation detector and test structures

processed on a silicon wafer.

Why

high resistivity Czochralski silicon?

Silicon detectors have traditionally been processed using Float Zone silicon (Fz-Si) wafers. Fz-Si crystals are grown without quartz crucibles acting as a source of impurities, i.e. oxygen, carbon, or boron. The lack of impurities results in high purity and high resistivity of the bulk silicon. Because of the high resistivity, the detector can be fully depleted at reasonable operating voltages. However, Fz-Si has a low oxygen concentration. The oxygen concentration can be increased by prolonged high temperature drive-in oxygen diffusion.

Unfortunately,

some metallic contamination is always

present in quartz tube diffusion furnaces.

At elevated temperatures, the diffusion

velocity of many harmful metals is much

higher than that of oxygen. This in turn may

lead to an extensive process induced

contamination in the silicon wafers, unless

a careful quartz tube cleaning procedure is

practiced.

Silicon wafers grown using

the

Czochralski method intrinsically contain

high level of oxygen, typically 10^17 –

10^18 cm-3.

In addition, the depletion

voltage of the Czochralski silicon (Cz-Si)

detectors can be tailored either by

adjusting the oxygen concentration in the

silicon bulk during crystal growth or by

manipulating the thermal history of wafers

during the detector processing.

Furthermore, using Cz-Si as detector

material may offer economical benefits.

Cz-Si wafers are available up to a diameter

of 450 mm while Fz-Si wafers are typically

of diameter 150 mm or 200 mm. Thus, very

large area silicon detectors could be

manufactured, which in turn could result in

significant savings in the costs related to

front-end electronics, interconnection, and

module assembly.

Crystal growth of Czochralski silicon

In the Czochralski method, polycrystalline silicon fragments are melted inside a quartz crucible.

During the process, argon gas continuously flushes the interior of the crucible and the surface of the silicon melt. Silicon single crystals are grown by slowly pulling a crystal seed up from the molten silicon, thus developing an ingot. Later, wafers are cut from the ingot. Oxygen concentration is one of the most important parameters of silicon wafers. For example, oxygen precipitates bind unwanted metallic impurities present during the processing of silicon devices. Furthermore, stress induced during high temperature processing can lead to the formation of slip defects in the wafer.

The presence of oxygen stabilizes the wafer, and thus Cz-Si wafers are less prone to slip than Fz-Si wafers. During crystal growth, oxygen is dissolved into silicon from the quartz crucible. Most of the oxygen is dissolved as silicon monoxide and is flushed away by argon gas. Furthermore, the resulting oxygen concentration depends on the velocity of the silicon melt flow as well as on the rate of oxygen evaporation from the surface of the melt. All these parameters can be influenced in order to get a desired oxygen concentration in silicon ingot. Since the silicon melt is an electrically conductive liquid, the magnetic field is an effective way to moderate and control the melt flow.

The Magnetic Czochralski (MCZ) method has several advantages, e.g. reducing the erosion of the silica crucible and thus reducing introduction of impurities during crystal growth. In order to grow n-type silicon ingots, phosphorous dopant is added to the silicon melt in order to create desired donor states in silicon. However, boron is a common element in nature and thus easily drifts from quartz crucible to silicon melt during crystal growth. Since boron acts as an acceptor in silicon, the amount of unwanted boron is an important limitation to the magnitude of resistivity in ntype silicon.

Fig 2.

Monocrystalline boules created using the

Czochralski process.

Conclusion

Anything missing? Write it here